|

Boiler Design Library

(February '24)

General

The aim of this library is to offer steamboaters approved designs of boilers suitable for a wide range of boats.

All the drawings contained in this document are copyright SBA Services Ltd and may not be reproduced or used without the permission of the Company.

The role of SBA Services Ltd (SBAS) in operating the boiler design library is strictly that of Librarian. The Company may in future commission new designs if it is felt appropriate and arrange for such designs to be approved by a competent person. SBAS does not have the necessary technical competence to comment on the design or approval process.

The designs in general, are for the pressure vessel only. The cladding, fittings and pipe work of the boiler are the responsibility of the owner. However some others (notably the John King water tube boilers) include a complete set of drawings for cladding and suitable fittings. These designs are marked ** in the listings.

Drawings are provided as printed and folded sheets, and some will include constructional details/guide (see those marked **).

Designs marked ( ^^ ) can be built without the need for a coded (certified) welder, therefore these "weldless designs" are suitable for construction by amateur engineers , without professional assistance.

Members who purchase a set of plans are strongly advised to consult a competent person or their boiler inspector before starting the construction of a launch boiler. The SBAS Construction Surveillance Service is designed to provide the required support and certification of the construction phase of a new boiler for professional or amateur constructors.

Users of these designs in countries other than the UK should check with the authorities in their own country that the design they choose is acceptable to their authorities.

Updated Library - February 2024

In order to maintain the quality of the Services we provide, and to reflect current practice, our Librarian (John Maltby) recently undertook a major review of the Library Designs and drawings.

As a result of this review we have moved some designs to a "reserve list", where the drawings, construction or assessment of the design require some work prior to being suitable for sale. We will maintain these designs on file, but would recommend users select from the "A List" designs shown below.

If an individual requires a copy of one of the "reserved list" designs, we will provide it at a quoted price which includes the cost of the work needed to bring the design, drawings and assessment up to our current standards and then move it to the "A List" for general sale.

We would also like to provide people thinking of having a boiler built with advice on the selection of an appropriate design, based on practical experience of many designs, boats and applications. Please contact us, using the links in this page, providing information on your planned usage and constraints.

If in any doubt please contact the SBAS for advice and help.

Conditions of Purchase

- 1. All the designs have undergone a design approval by a competent person to standards detailed in the United Kingdom 'Pressure Equipment Regulations 1999". Although it is recognised that marine boilers are an exempt category, the regulations specify current best practice. The assessment applies strictly to the documents held in the library, and any alterations to the design made by the user (even details) may render the assessment invalid. It is the responsibility of the purchaser of a library design to obtain a Competent Person’s assessment of any alterations made to that design. The SBAS can provide this, if needed, via our Boiler & Pressure System Design Assessment Service .

- Notes on Manufacture and Inspection

- 2.1 The compliant construction of a boiler within the UK is the responsibility of the boiler maker and the competent person appointed to witness satisfactory construction.

- 2.2 The appointment of a competent person to witness satisfactory construction of the boiler is the responsibility of the boiler maker.

- 2.3 Where the purchasers of the design are intending to construct the boiler themselves (rather than through a commercial boiler maker), it is vitally important that they agree with their Boiler Inspector how the condition in 2.1 above relating to the appointment of a competent person to witness satisfactory construction is to be implemented before any construction is started. If they intend their boiler to be inspected by SBAS and do not yet have a boiler inspector, they should contact the SBAS Boiler Inspection Scheme Administrator so that one may allocated to them. (see SBAS Boiler Inspection Scheme page)

- 2.4 Any boiler to be accepted by SBAS for inspection & issue of a boiler certificate must comply with the requirements of 'The Purpose, Operation & Requirements' booklet issued by SBAS. Of particular importance is section 4.1 Preliminaries. (A copy of the booklet is available from the SBAS Boiler Inspection Scheme Administrator), (see SBAS Boiler Inspection Scheme page).

- Copyright subsists on the designs in the library and is owned by SBAS. Copies of the design documents are supplied to members on the condition that they are for the member’s personal and private use. It would be a breach of copyright to (inter alia) pass on the documents for use by another person; make copies of them; or use them for any commercial purpose.

- Purchase of a set of drawings is for the construction of one boiler.

- SBAS accepts no liability that the boiler will perform in accordance with any estimates shown on the drawings. Purchasers must ensure that the boiler will be suitable for their proposed application. The SBA website forum pages & the Steam Boat Register may give helpful guidance on this matter. SBAS Boiler Inspectors or Librarian may also be able to help in providing this guidance.

- Purchasers of designs are deemed to be in agreement to the above conditions

- Cash with order (BACS transfer for UK customers is preferred).

- International Customers may pay using SWIFT/IBAN using these codes IBAN - GB05ABBY09015005469082, SWIFT code - ABBYGB2LXXX there is a 15% surcharge for this payment method to cover costs charged by payee's bank.

- Prices include VAT but not postage and packing

- Typical delivery time 18 days.

Prices and Ordering

You can order a full set of printed drawings for a design, for £100 (plus post and packing) by clicking the link below. This will generate an order request. We will respond with a confirmation, order number and payment details.

Ordering your Boiler design drawings: Click this link and we will create an email you can complete and send. We will respond with a proforma invoice and order number.

SBA Services Ltd

Library of Boiler Designs

Note: all information and drawings in this table are indicative only. The delivered drawings are the definitive version of the design.

| Performance and Application Notes | |||||||

| Design Num | Description | Sample GA Drawing (Click Image for a larger View) |

Heating Surface sqFt/sqM |

Working Pressure |

Typical Usage | ||

| Fire Tube Boilers | |||||||

| VFT 101 |

Welded Vertical Fire Tube |

|

11.4/1.06 | 200psi/13.6bar | Elidir | ||

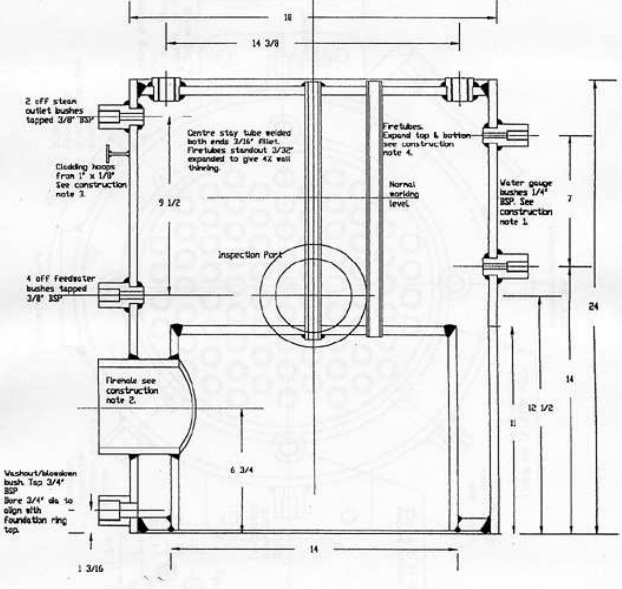

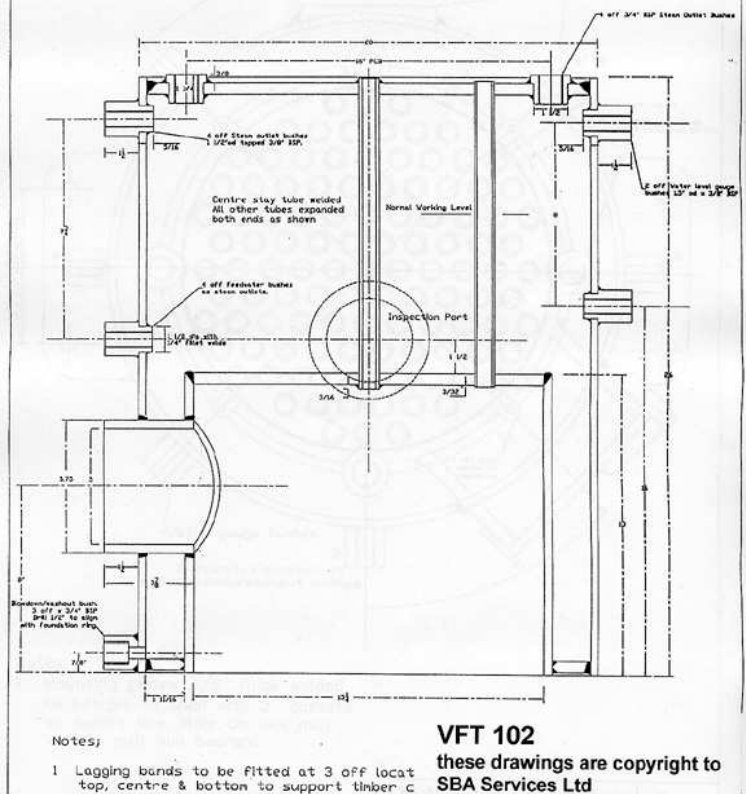

| VFT 102 |

Welded Vertical Fire Tube |

|

17.6/1.63 | 200psi/13.6bar | Anna, Dyad, Grayling, Obsidian | ||

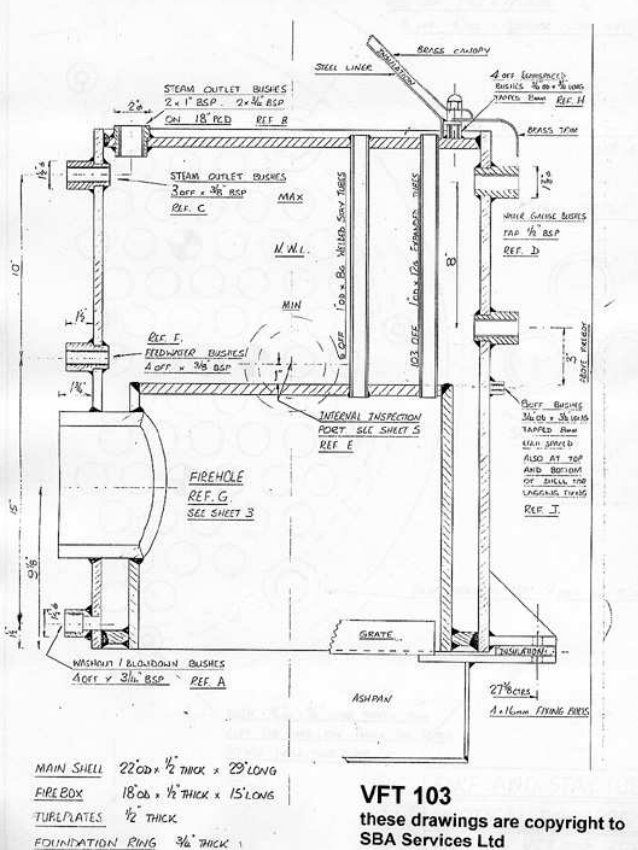

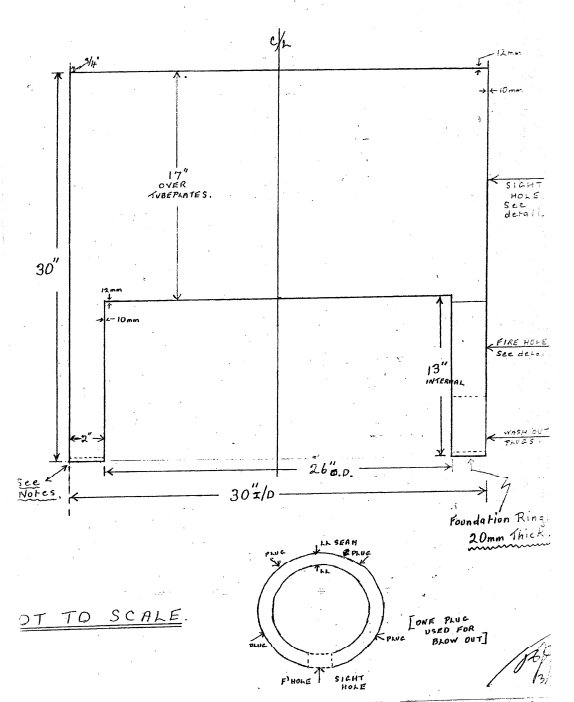

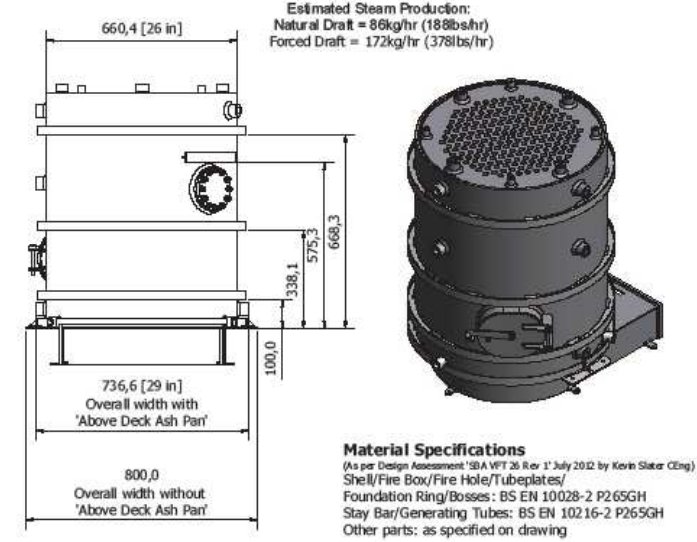

| VFT 103 |

Welded Vertical Fire Tube |

|

24.1/2.24 | 200psi/13.6bar |

Suliven, Nokomis, Niad, Araminta, Quetzal, Roundtuit, Tambora |

||

| VFT 104 |

Welded Vertical Fire Tube |

|

60.8/5.64 | 180psi/12.4bar | |||

| VFT 105 |

Welded Vertical Fire Tube |

|

37.0/3.52 | 200psi/13.78bar | Bluebell, Moondance, Wide Awake | ||

| Water Tube Boilers | |||||||

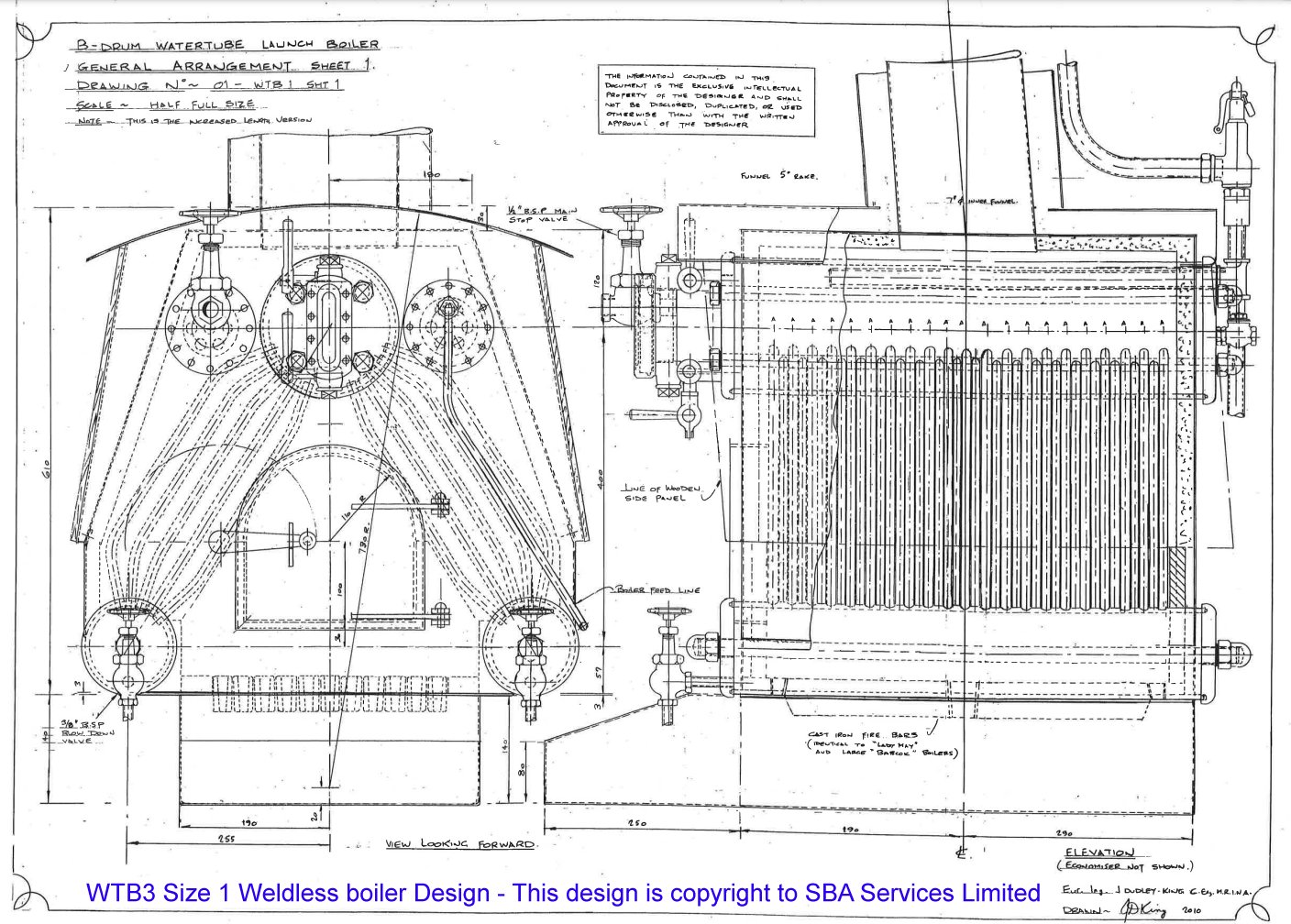

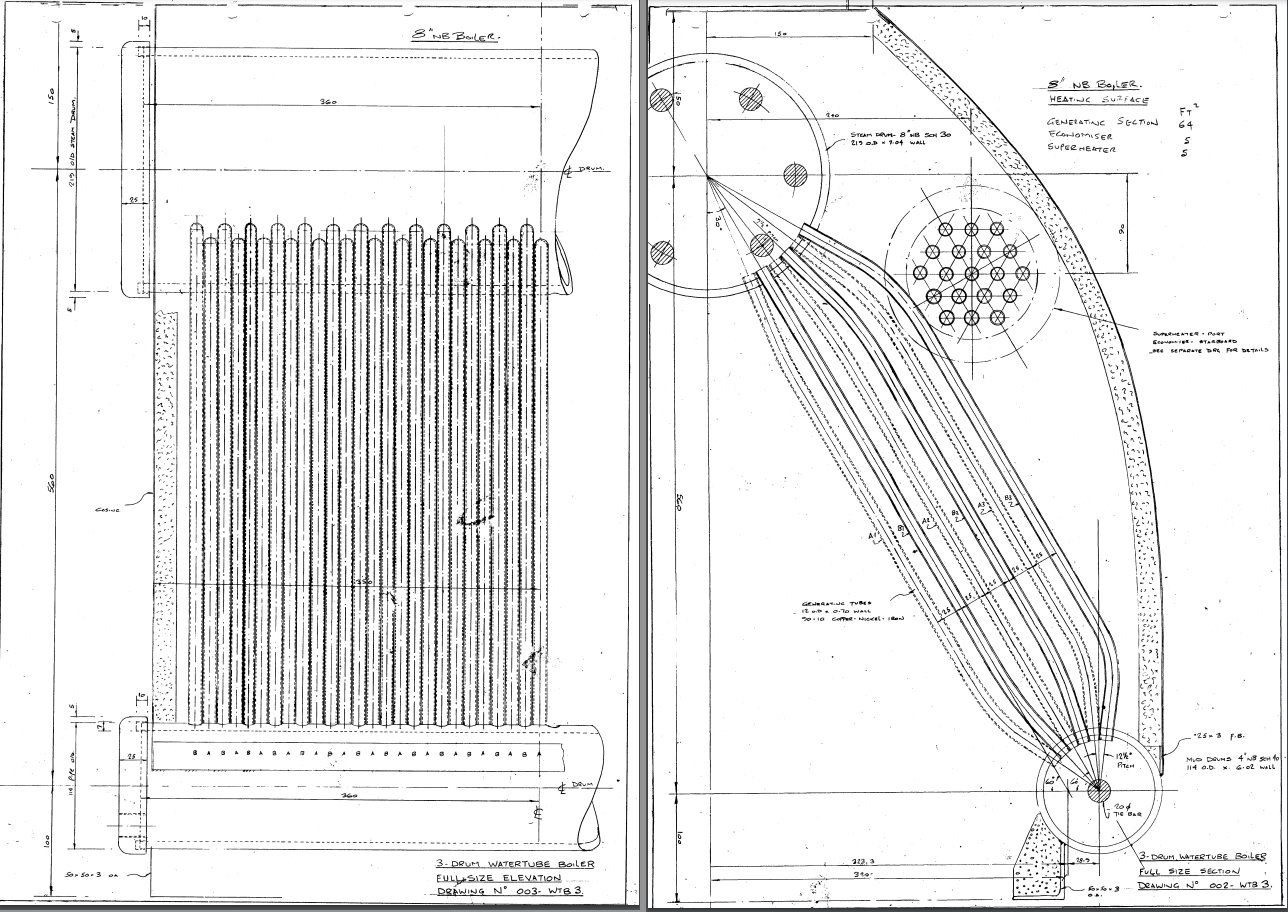

| WTB 3-1 ^^ ** |

Three-Drum John King weldless Yarrow design |

|

32/2.97 | 250psi/ 17.24bar | SY Befur, Lady Amanda (well suited to liquid (pressure jet) fuel or coal firing) | ||

| WTB 3-2 ^^ ** |

Larger 3-Drum John King weldless Yarrow design |

|

64/5.9 (plus 5sqft economiser and 5sqft superheater) |

250psi/ 17.24bar | (well suited to liquid (pressure jet) fuel or coal firing) |

||

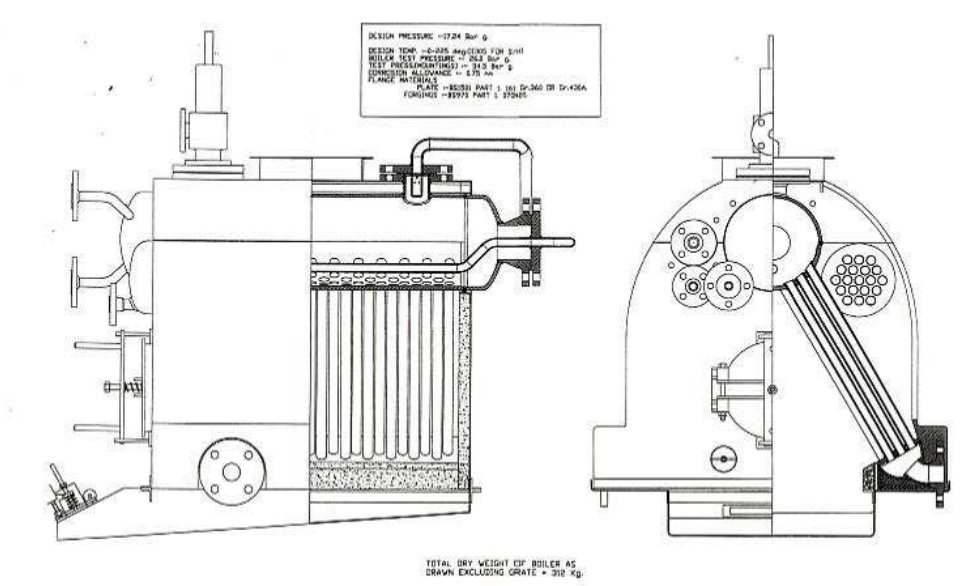

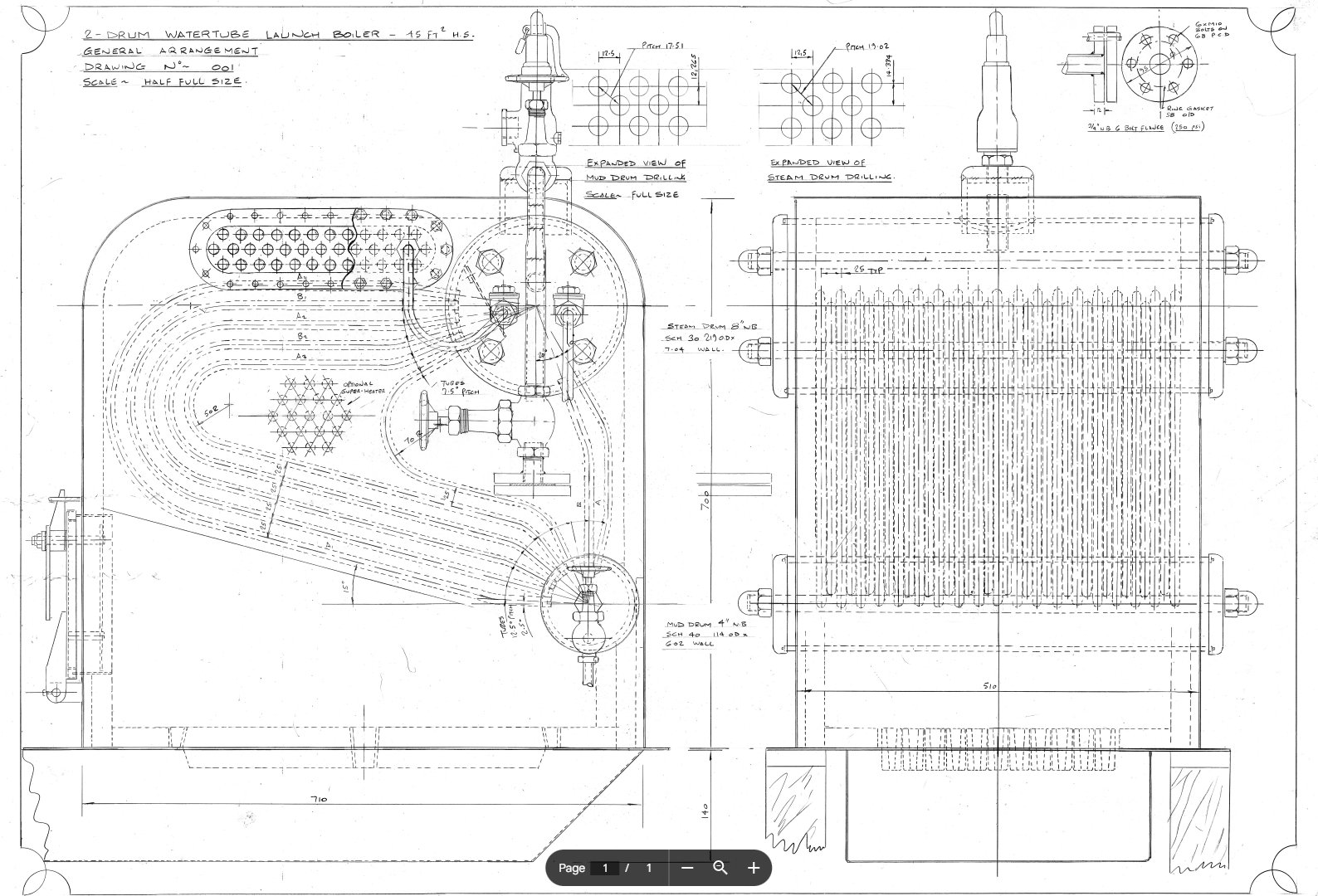

| WTB 10 |

3-Drum Welded Water-Tube design Steam Drum: 8" dia Length 30" D-section mud drums Grate Area 3.1 sqft Weight: 312Kg |

|

60/5.25 | 225psi/ 15.52bar | Anachronism | ||

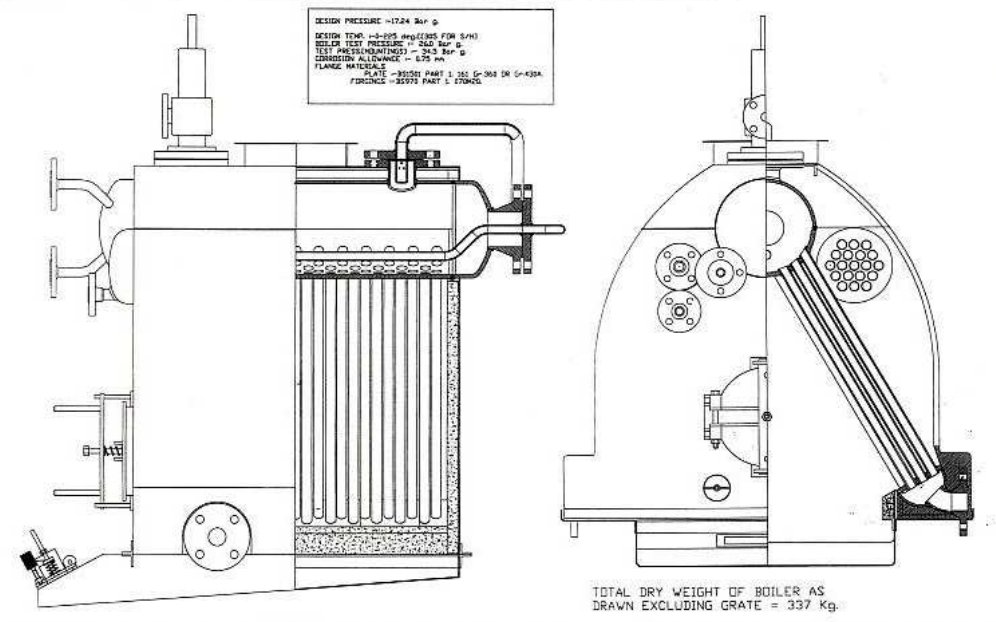

| WTB 11 | 3-Drum Welded Water-Tube design Steam Drum: 10" dia Length 36" D-section mud drums Grate Area 3.9 sq ft Weight: 337Kg |

|

72.5/6.75 | 225psi/ 15.52bar | |||

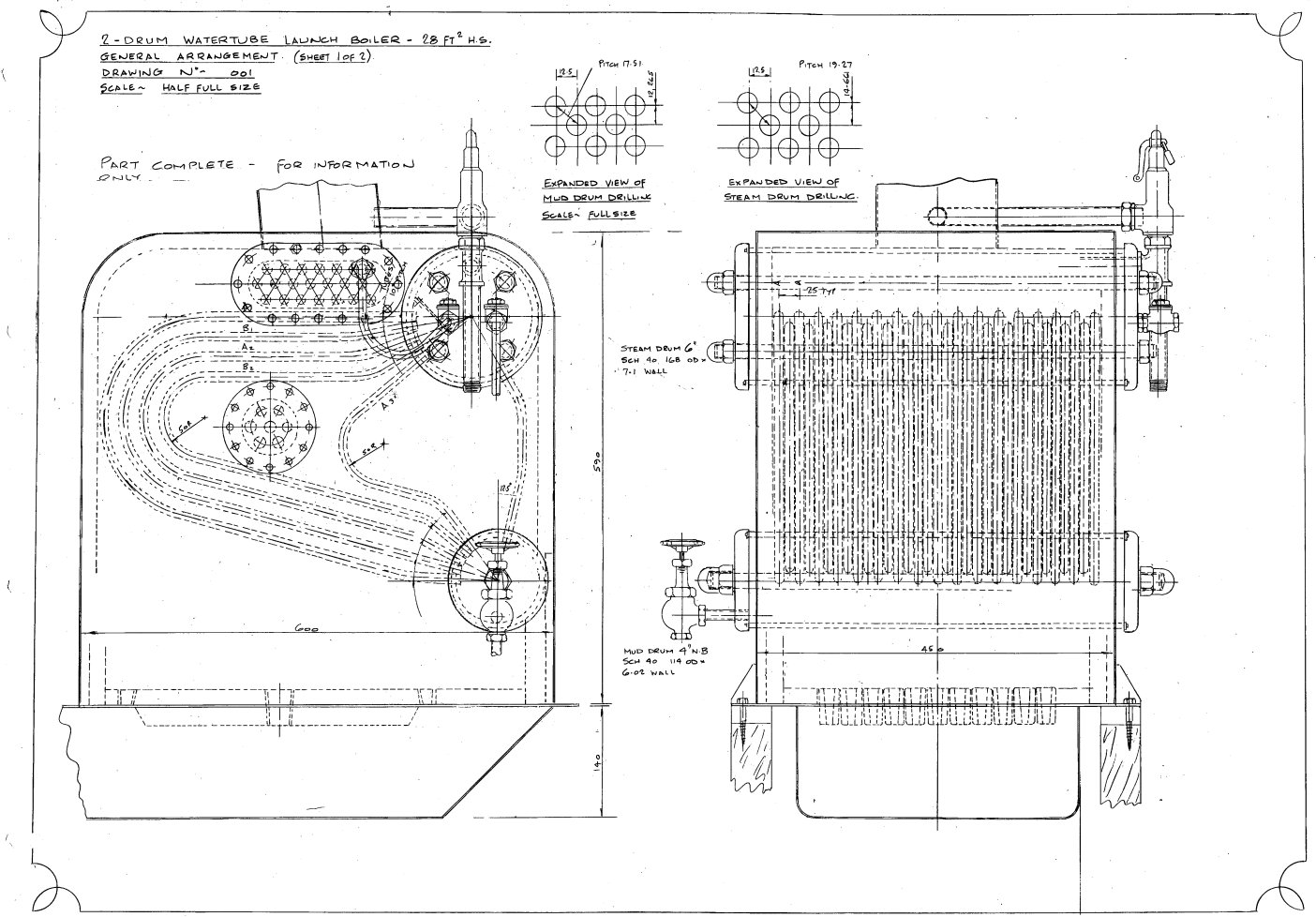

| WTB12 ^^ |

2-Drum weld-less water tube design, with 6 inch steam drum.(optional welded steam dome) John King design. (JK water-tube Design Notes) |

|

28.0/2.6 | 250/17.24 | |||

| WTB 13 ^^ |

2-Drum weld-less water tube design, with 8 inch steam drum.(optional welded steam dome) John King design. (JK water-tube Design Notes) |

|

45/4.18 | 250/17.24 | |||

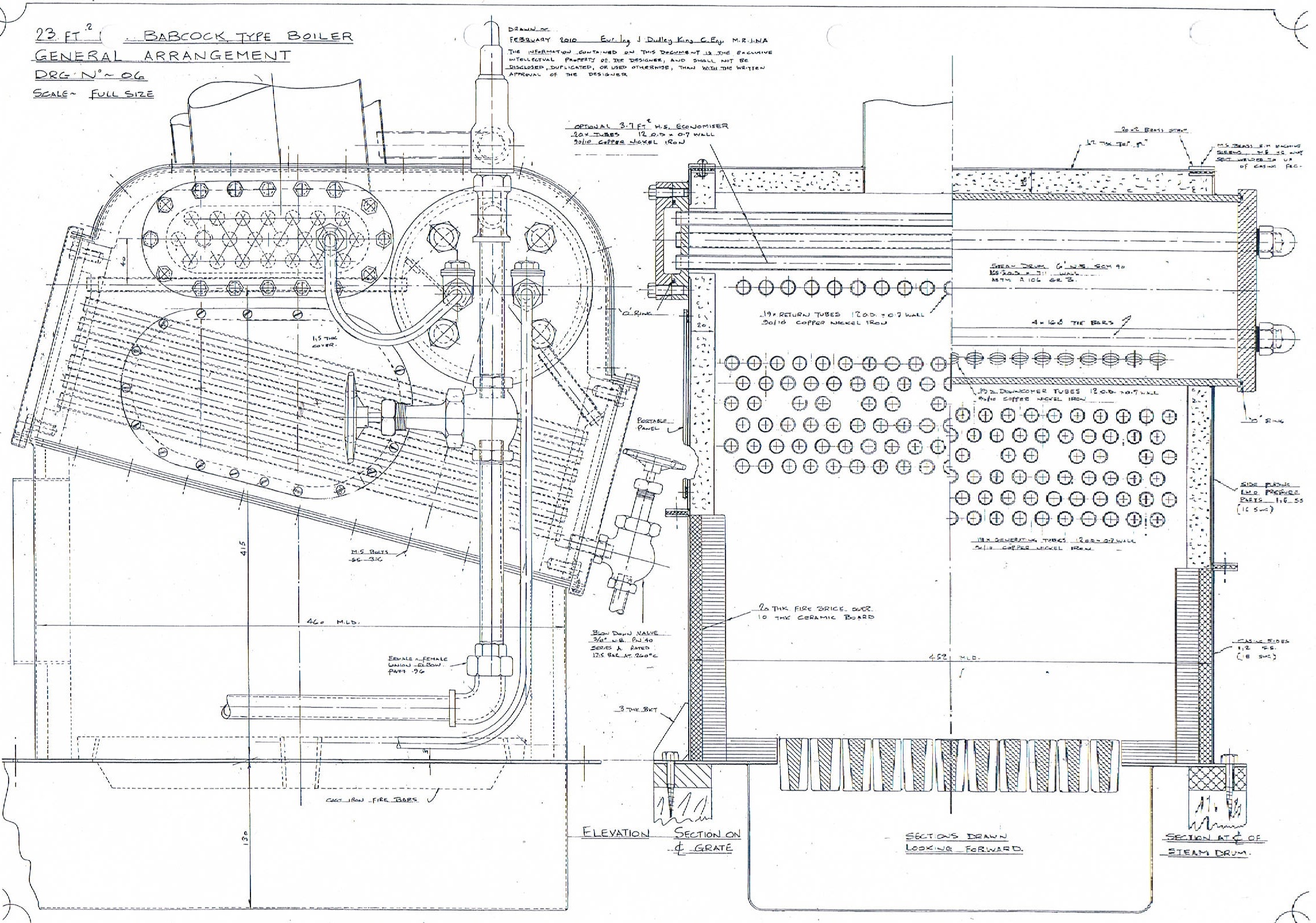

| WTB 14 ^^ |

Weld-less Babcock - 23 sqFt (optional welded steam dome) John King design. JK's notes on Babcock design. |

|

23/2.13 | 250/17.24 | |||

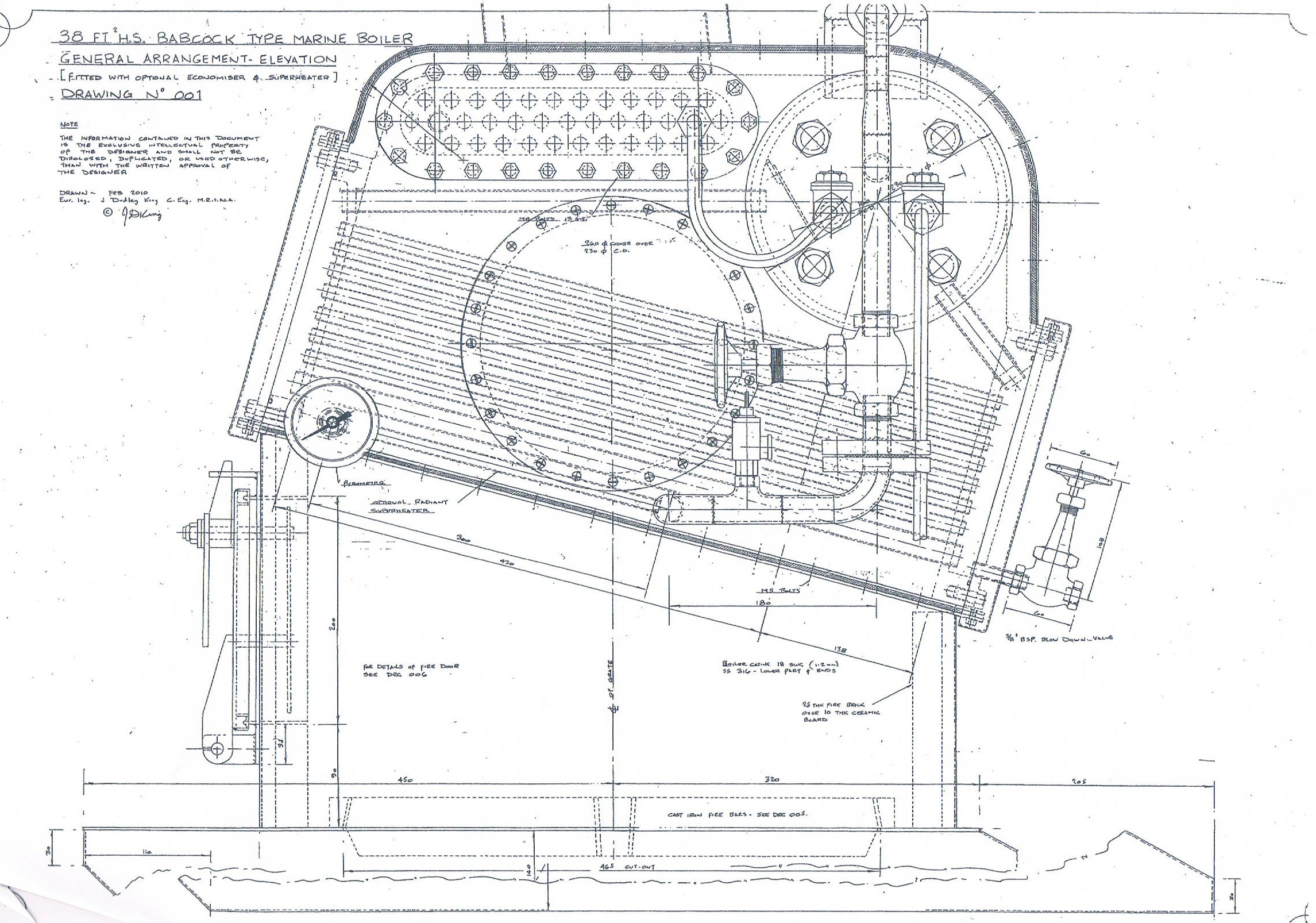

|

WTB 15 |

Weld-less Babcock - 38 sqFt (optional welded steam dome) John King design. JK's notes on Babcock design. |

|

38/3.5 | 250/17.24 | |||

| Locomotive Type | |||||||

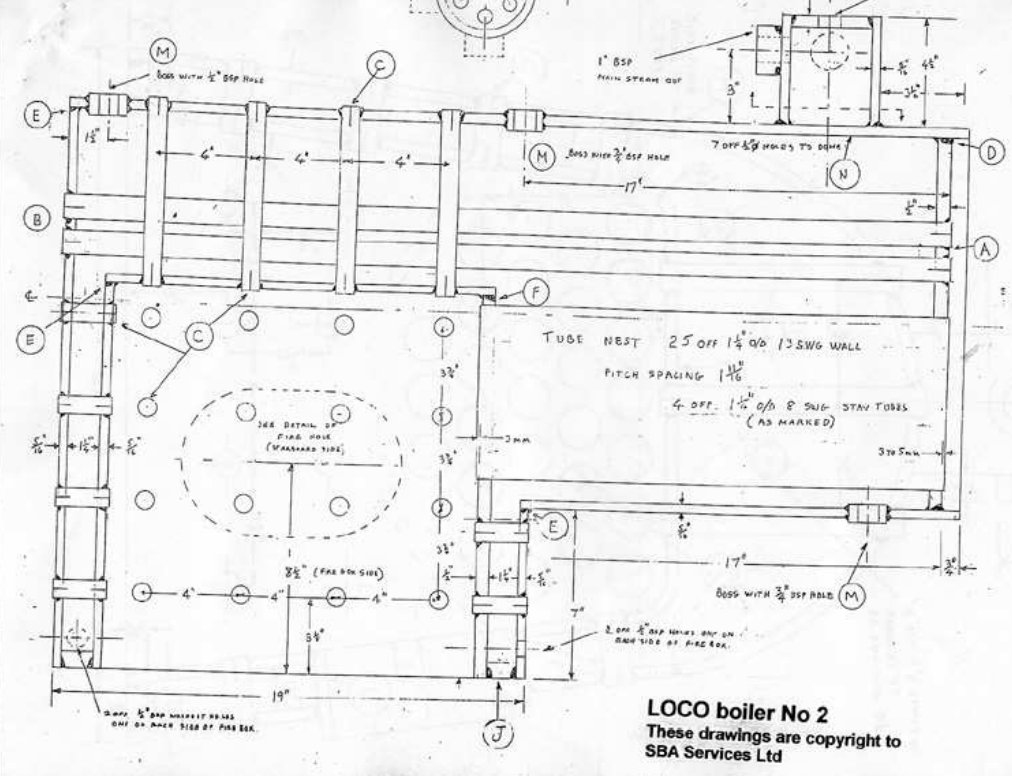

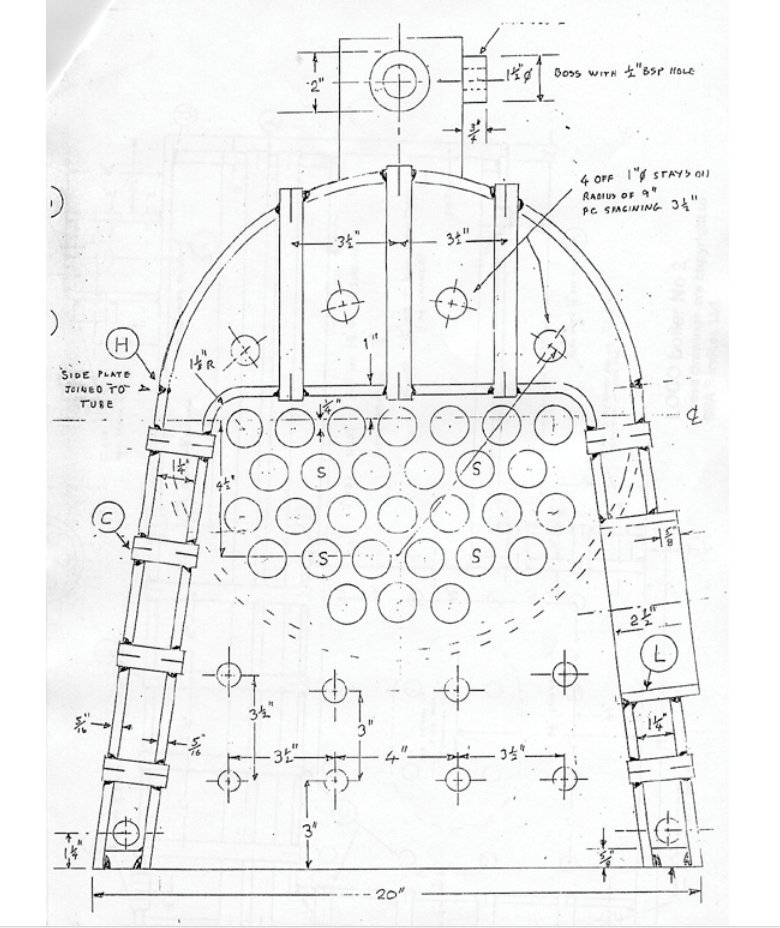

| Loco 2 | Welded. Firebox: Height 22" (56cm), Width 20" (51 cm), Length 19" (48cm). Barrel: 16" (37 cm) dia, length 18" (46cm). Tubes: 25 of 1.25" 13swg and 4 x 8 swg (tube stays). (A version with inclined tubes also available - "Loco Mod 2") Weight: ~250kg |

136kg/hr evaporative rate | 200psi/13.7bar | Arlette, Annabelle, Hero, Anna Jayne, Sans Son | |||

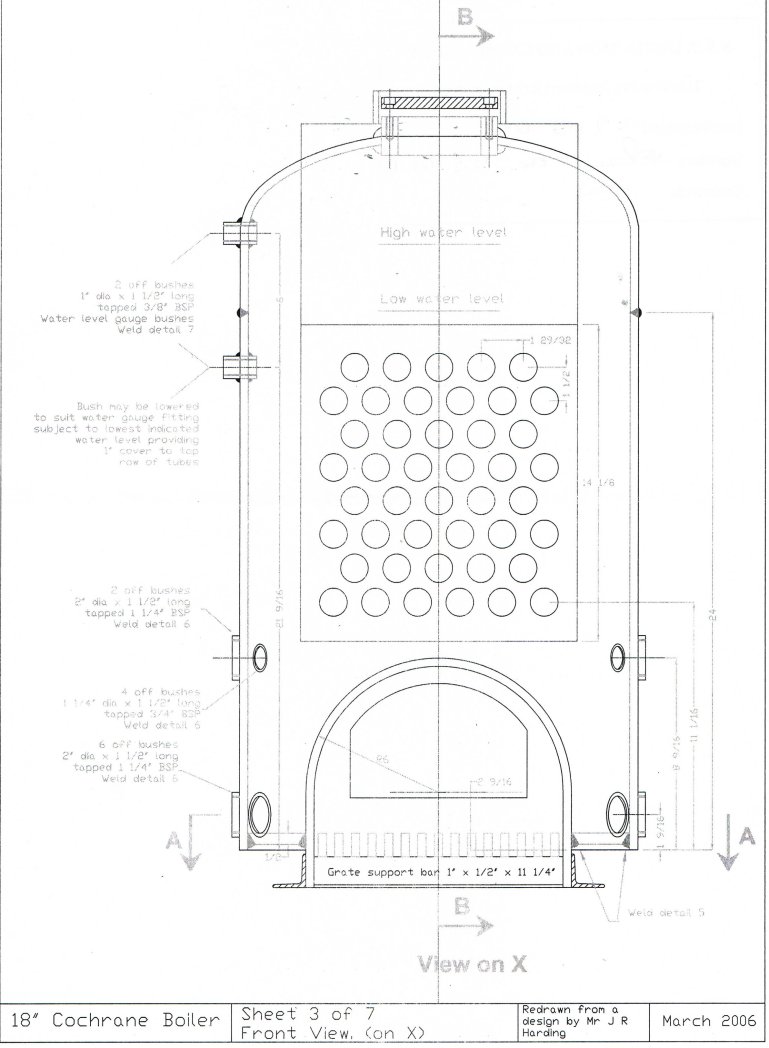

| Horizontal fire tube boiler | |||||||

| HFT 1 | Cochran type. Welded. Diameter 18" (45.7cm), Height 24" (61.0cm), Tubes: 44 of 1.25" dia (2.3cm dia) |  |

19/1.76 | 240psi/ 16.3bar | |||

The Steam Boat Association of Great Britain

The Steam Boat Association of Great Britain